By Lynn A. Kirshbaum, Deputy Director

Historically, CHP units have run on traditional fuels, and many today use natural gas. This use of CHP can be thought of as “CHP 1.0,” the first wave of CHP technologies that relied on fossil fuels. However, CHP units can be fueled by renewable and lower-carbon fuels such as biogas, renewable natural gas (RNG) or biomethane, and hydrogen, or “CHP 2.0.” Use of these lower-carbon fuels can allow CHP systems to reduce emissions even further than they do under CHP 1.0. Renewable and lower-carbon fuel technologies can serve as the primary fuel source for CHP systems and further reduce emissions across the industrial, commercial, and municipal sectors. Moreover, CHP systems will use these fuels efficiently, requiring less renewable and lower-carbon fuel inputs for the same energy outputs compared to other generation units.

Fuels such as biogas and RNG are already being used in CHP systems, and additional existing systems could run on these fuels, providing a near-term solution for further emissions reductions. Generation equipment currently running on traditional fuels may be able to transition to lower-carbon fuels, including biogas, RNG, and hydrogen. In addition, using existing gas pipeline infrastructure can be a low-cost option for delivering these new fuels, and current research is examining how this existing infrastructure can accommodate the distribution of hydrogen gas.

Work is also being done to increase the volume of hydrogen fuel that can be used in CHP systems. For example, gas turbine manufacturers are looking to provide equipment that can accommodate higher percentages of lower-carbon fuels: various companies in the U.S. and abroad are deploying or working on hydrogen-ready technology, and in 2019, a number of European companies committed to provide gas turbines that can handle 20% hydrogen content in fuel by 2020, and 100% by 2030. Hydrogen fuel for CHP systems is not yet widespread but could see more extensive use in the future as technologies develop to produce hydrogen fuel and transport it as necessary.

Work is also being done to increase the volume of hydrogen fuel that can be used in CHP systems. For example, gas turbine manufacturers are looking to provide equipment that can accommodate higher percentages of lower-carbon fuels: various companies in the U.S. and abroad are deploying or working on hydrogen-ready technology, and in 2019, a number of European companies committed to provide gas turbines that can handle 20% hydrogen content in fuel by 2020, and 100% by 2030. Hydrogen fuel for CHP systems is not yet widespread but could see more extensive use in the future as technologies develop to produce hydrogen fuel and transport it as necessary.

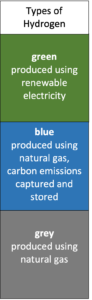

Hydrogen fuel is commonly produced through a thermal process known as natural gas reforming, or through electrolysis using domestic resources like nuclear power, biomass, solar, and wind. There are different types of hydrogen that distinguish how it is produced, which has impacts on its overall emissions: grey hydrogen is produced industrially from natural gas, generating significant carbon emissions; blue hydrogen is also produced from natural gas, but its carbon emissions are captured and stored, or reused; and green hydrogen is generated though electrolysis of water by using renewable energy sources that do not produce carbon emissions. Using electricity from wind turbines and solar panels to power the electrolysis process and produce hydrogen is still under development, but has seen increased interest.

This interest is demonstrated throughout the world where hydrogen production facilities are under development or consideration, including in California, Utah, New York, Germany, Denmark, Canada, and Australia.

Transportation and storage of hydrogen is another challenge to widespread adoption of hydrogen fuel in the near-term. The initial capital costs of new pipeline construction for hydrogen gas are a barrier to expanding hydrogen pipeline delivery infrastructure. Transporting gaseous hydrogen through existing pipelines is a low-cost option for hydrogen delivery, though further research is needed, and being conducted, on the implications of transporting hydrogen through existing pipelines. However, in the near-term, distributed generation technologies such as CHP can be deployed at the point of hydrogen production. This would allow the use of hydrogen fuel in CHP systems, and realization of the corresponding emissions benefits, while the development of hydrogen-ready pipelines is still underway.

The Hydrogen Council, an international coalition of energy, transport, and industrial companies interested in hydrogen propagation published a study entitled, “The Path to Hydrogen Competitiveness.” In this report, they estimate that hydrogen has the potential to achieve 18% of global end energy demand by 2050. The amount of emissions reductions that can be achieved by this increase in hydrogen use will depend on the source of the hydrogen fuel, as described above. Currently, 99% of global hydrogen is produced using fossil fuel sources, accounting for 830 Mt CO2/year, more than the entire country of Germany. As the hydrogen economy grows, a switch towards lower-carbon hydrogen production options for both existing and added production could result in significant emissions reductions.

Using lower-carbon fuels such as hydrogen in CHP units, or CHP 2.0, can allow CHP systems to reduce emissions even further across the industrial, commercial, and municipal sectors. CHP systems will use these fuels efficiently, requiring less lower-carbon fuel inputs for the same energy outputs compared to other generation units. Though hydrogen fuel for CHP systems is not yet widespread, it could see more extensive use in the future as technologies develop to produce hydrogen fuel and transport it as necessary.

Learn more about CHP as a climate change solution by reading our report, CHP and a Changing Climate: Reducing Emissions and Improving Resilience.

Learn more about hydrogen and CHP by reading our blog posts CHP and renewable fuels, the day 2 wrap-up of the 2020 National Summit on CHP, Insights from the “Low Carbon CHP: Hydrogen” Panel at the Summit.

Stay updated about future CHP Alliance events by clicking here to be added to our mailing list.